VIM 真空熔煉爐

詳細介紹

• Double-walled, water-cooled melting chamber with hinged swing-away chamber door

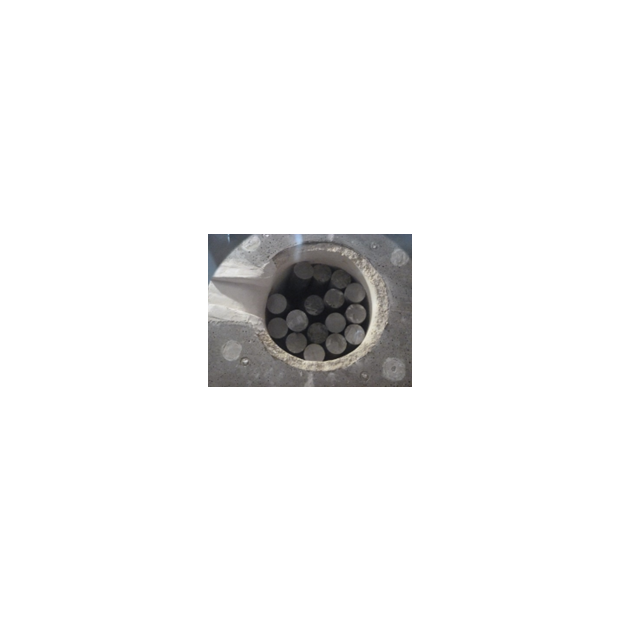

• Tiltable melt box mounted on the inside of the swing-away chamber door

• Electrically driven turntable for exact positioning the molds in front of the crucible

• Feed-through ports in the chamber wall for the use of instrumented molds

• Feeding and charging chamber at the top of the melting chamber with isolation valve

• Temperature, sampling and charging manipulator

• Loading and unloading cart for ergonomic operation

• Vacuum pump stand

• Energy and media supply

• Control system

• Maintenance platform for operating the late feeding

chamber and observation of the melting and casting

process via view ports

This design results in the following advantages:

• Simple cold charging of the induction furnace with opened

melt chamber door;

• Easy loading and unloading of the molds via a loading and

unloading cart;

• Precision pour control with optimum spout position during

furnace tilting for maximum pouring accuracy;