單晶鑽石長晶設備

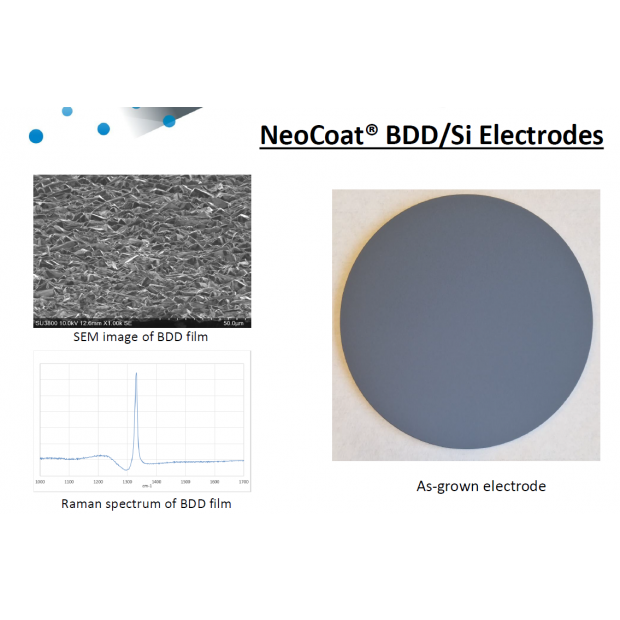

NEOCOAT 瑞士 BDD/Si Electrodes

NEOCOAT 瑞士 BDD/Si Electrodes

Spare parts 100% compatible with JAPAN Water GS-KD Systemused in silicon chip foundries

Excellent customer satisfaction and feed-back

Large area NeoCoatCVD reactors allow producing such electrodes per batches of 15 units

Excellent customer satisfaction and feed-back

Large area NeoCoatCVD reactors allow producing such electrodes per batches of 15 units

詳細介紹

Application: Resist removal in wet-benches with sulfuric acid and hydrogen peroxide mixture (SPM) also called Caro Acid or Piranha Solution

Process: Production of peroxodisulphuricacid (Piranha solution) by in-situ electrolysis of sulfuric acid with boron doped diamond (BDD) electrodes

Assets: Avoid continuous addition and mixing of dangerous chemicals in wet-benches and ensure using a freshly produced, reactive and reproducible solution

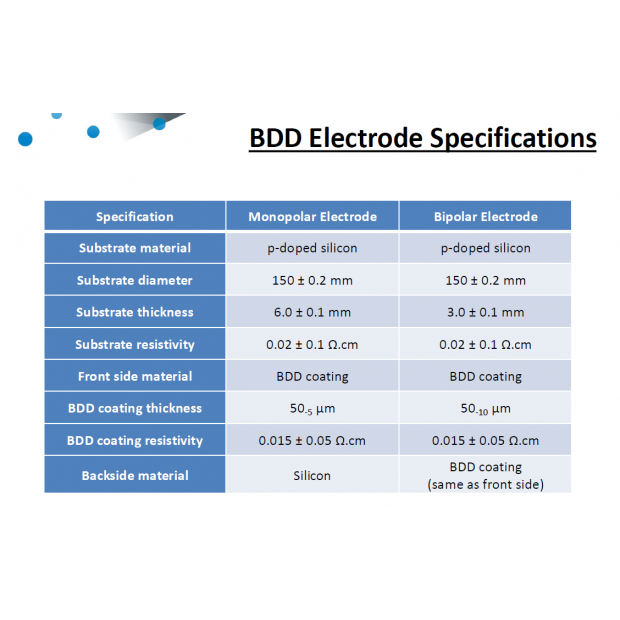

BDD electrodes need to be changed periodically as BDD film is slowly etched by Caro acid

NeoCoat® BDD/Si electrodes are already qualified by big semiconductor customers as spare parts for GS-KD system and used in their chip foundry

NeoCoatoffers very competitive pricing compared to original equipment manufacturer parts