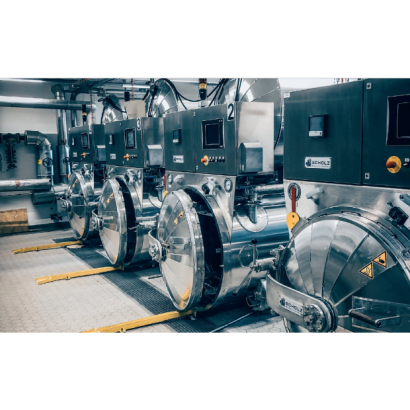

產品應用:

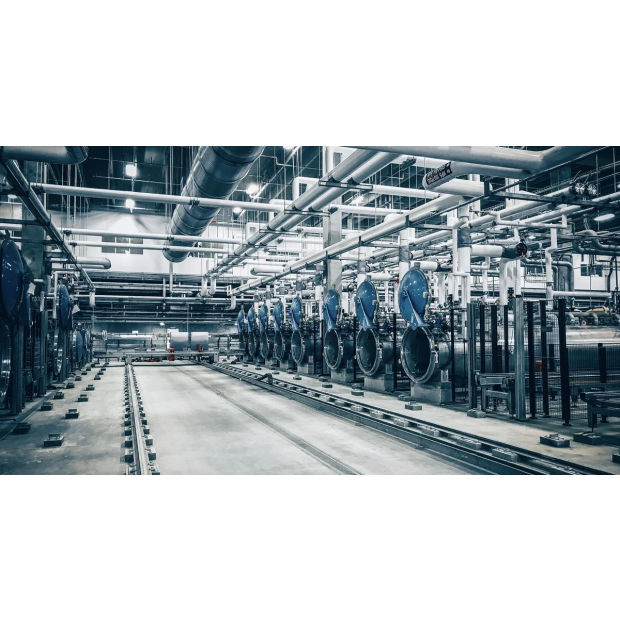

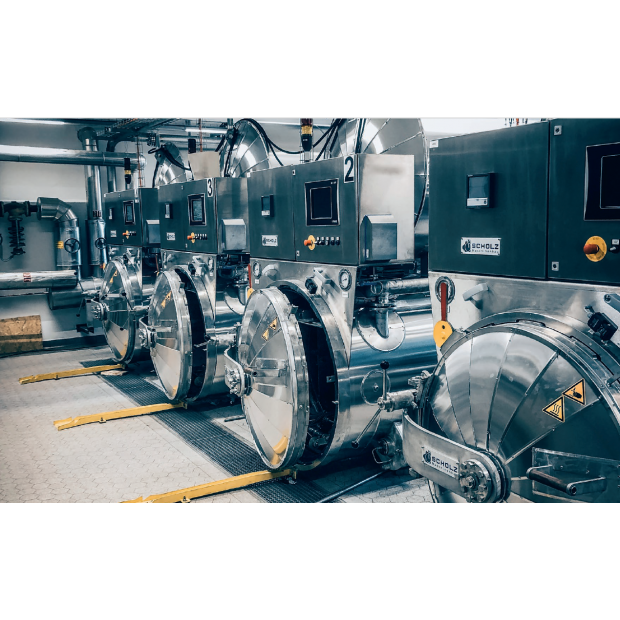

包裝, 鐵罐, 玻璃罐,塑膠瓶等

Benefits 優勢:

Savings, Homogeneity, Axiom, Security

Savings 能源節約

只使用您需要的:透過直接蒸汽注入,蒸汽消耗得到最佳化。實際:改善了使用成本(TCO - 總擁有成本)

Homogeneity 均勻性

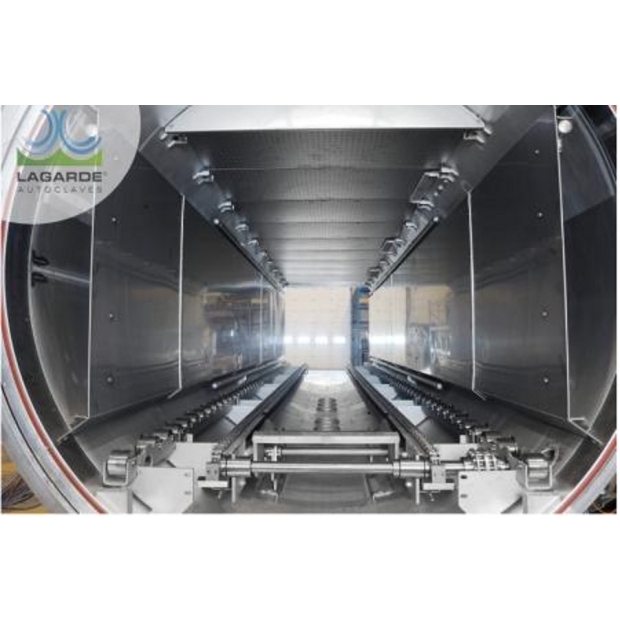

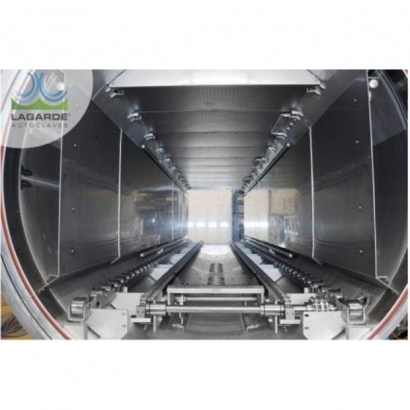

對於傳統的水蒸餾器,熱傳流體(液態水)僅在位於淋浴器中的產品上從頂部流向底部,並且僅在待處理產品的部分交換表面上流動。 1972 年,拉加德發明了蒸汽空氣技術,蒸汽(水的氣態)將佔據整個外殼,因此產品將與待處理產品的整個表面進行交換

Axiom公理

正如科學文獻中所提到的,拉加德蒸汽和空氣系統是唯一能夠處理所有包裝的工藝,這得益於氣體特性、風扇強制循環和拉加德微弱冷卻系統的綜合優勢。

Security安全性

獨立壓力和包裝形狀的溫度精度(控制強制通風)

– 與噴水系統相比,沒有傘狀效應

– 由於採用了 Lagarde 微弱冷卻系統,因此不會出現熱衝擊:熱分布精度可在+/- 0.2°C內。

– 循環過程中不存在噴嘴阻塞的風險